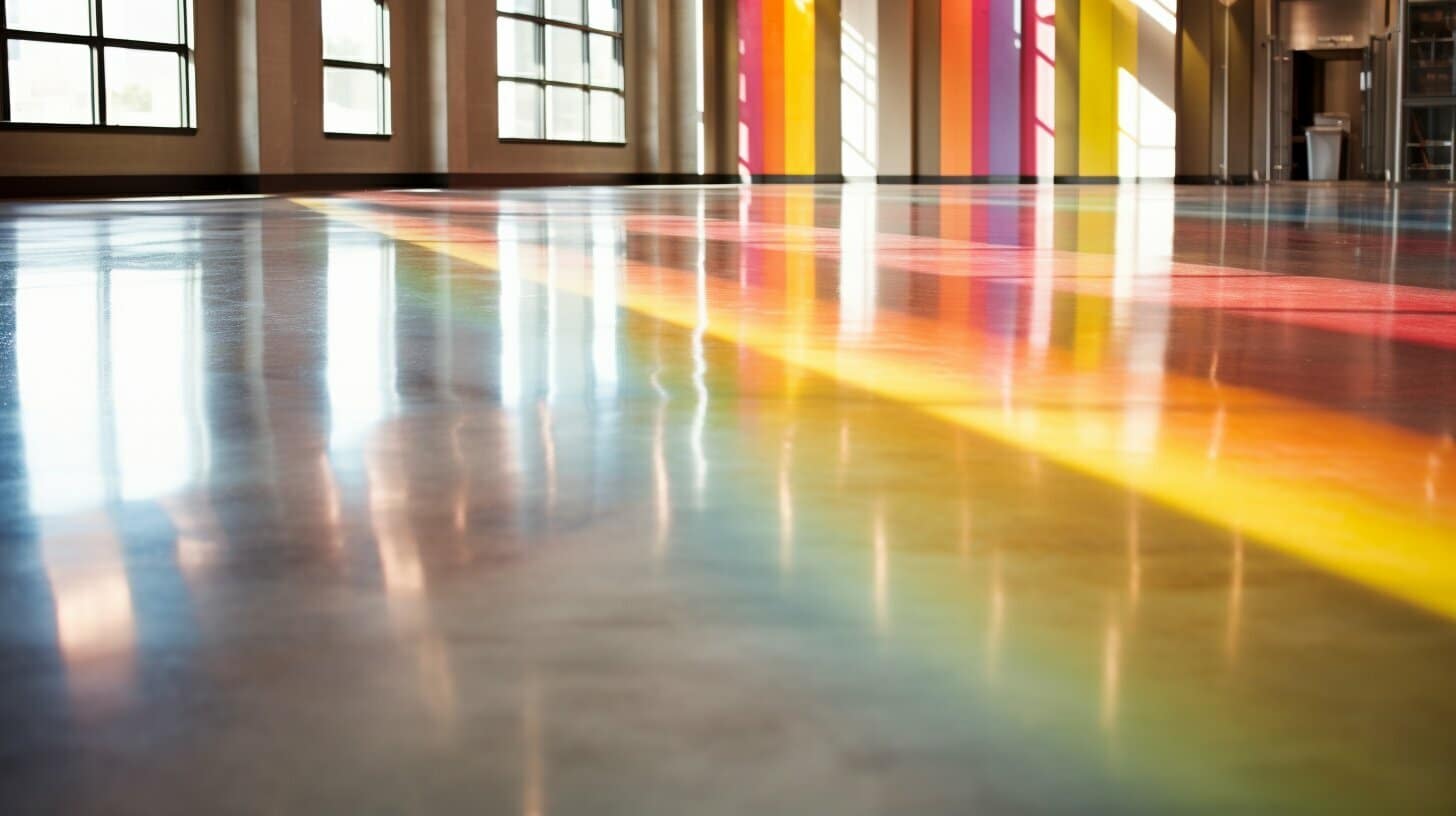

Polished concrete offers a wide range of design possibilities, including the option to add vibrant colors or dyes to create a customized appearance that suits your style and preferences. This versatile material is commonly used in areas with heavy traffic, such as warehouses, retail stores, hotels, and office buildings, due to its affordability, durability, low maintenance, and environmental friendliness.

Whether you want to enhance the aesthetics of your polished floors or create visually appealing outdoor spaces, colored or dyed concrete can provide the solution. By using colored concrete, you can add vibrancy to your surfaces, creating decorative patterns and designs that add visual interest. On the other hand, concrete stains can transform your floors with unique and natural-looking color variations, mimicking the appearance of other materials like marble or wood. Concrete dyes, on the other hand, offer the opportunity to create bold and vivid polished surfaces with a wide range of intense colors and effects.

The process of coloring or dyeing polished concrete requires expertise and specialized equipment. That’s why it’s recommended to hire professional concrete polishing contractors who have the knowledge and experience to achieve the desired results. These experts can guide you through the process, ensuring your polished concrete surfaces are beautifully colored or dyed to your specifications.

Key Takeaways:

- Polished concrete can be colored or dyed to create a customized appearance.

- Colored concrete adds vibrancy and can create decorative patterns and designs.

- Concrete stains provide unique and natural-looking color variations.

- Concrete dyes offer bold and vivid colors with various effects.

- Hiring professional concrete polishing contractors is recommended for coloring or dyeing polished concrete surfaces.

Exploring Coloured Concrete: Adding Vibrancy to your Surfaces

Colored concrete is a popular choice for adding vibrant hues and creative designs to polished surfaces, allowing you to create a unique and eye-catching look for your floors or other concrete elements. The process of coloring concrete involves adding pigments to the concrete mix before it is poured, ensuring that the color is consistent throughout the material. This offers an endless range of possibilities for achieving the desired aesthetic.

One advantage of colored concrete is its ability to provide long-lasting color that does not fade over time. Unlike surface coatings or paints, which can chip or peel, colored concrete is a permanent part of the material, ensuring that your design remains vibrant for years to come. This makes it a durable and cost-effective choice for both residential and commercial applications.

Another benefit of using colored concrete is the ability to create decorative patterns and designs. By combining different colors or using techniques like acid etching or stenciling, you can achieve intricate and personalized designs on your polished surfaces. Whether you want a bold and modern look or a subtle and sophisticated finish, colored concrete offers endless possibilities for customization.

| Benefits of Colored Concrete |

|---|

| Long-lasting color |

| Durable and cost-effective |

| Allows for decorative patterns and designs |

Colored concrete is a versatile option for enhancing the beauty of your polished surfaces. Its ability to provide vibrant hues, durability, and customization options make it a popular choice for homeowners and businesses alike. Whether you want to add a pop of color to your floors or create a unique design, colored concrete offers a solution that is both aesthetically pleasing and long-lasting.

Transforming Concrete with Stains: Enhancing the Beauty of Polished Floors

Concrete stains offer a versatile and transformative way to enhance the beauty of polished floors, adding depth and character with their unique color variations and mimicking the look of other materials. By penetrating the surface of the concrete, stains create a natural and organic appearance that can mimic the elegance of marble or the warmth of wood. With a wide range of stain colors available, you have the freedom to choose the perfect shade to complement your space.

Stained concrete can be used to create various effects, from subtle and understated to bold and eye-catching. Whether you prefer a uniform color throughout or a more intricate pattern or design, stains can bring your vision to life. The color variations and mottled effects created by stains add visual interest and depth to polished floors, making them a standout feature in any residential or commercial setting.

When considering stained concrete for your polished floors, it is important to work with professional concrete polishing contractors who have the expertise and knowledge to achieve the desired results. They have the specialized equipment and techniques necessary to properly apply stains and ensure a seamless and flawless finish. By entrusting your project to professionals, you can be confident that your stained concrete floors will enhance the beauty of your space and withstand the test of time.

| Benefits of Stained Concrete |

|---|

| 1. Creates a unique and natural-looking appearance |

| 2. Offers a wide range of color options to suit any style |

| 3. Adds depth and character to polished floors |

| 4. Mimics the appearance of other materials, such as marble or wood |

| 5. Provides long-lasting and durable results |

In conclusion, stained concrete is a fantastic option for enhancing the beauty of polished floors. With its ability to create unique color variations and mimic the look of other materials, stained concrete offers a truly transformative solution. By working with professional concrete polishing contractors, you can ensure that your stained concrete floors are expertly executed, resulting in a stunning and durable finish that will impress for years to come.

Dyeing Concrete: Creating Bold and Vivid Polished Surfaces

Dyeing concrete offers a fantastic opportunity to create polished surfaces with bold and vivid colors, allowing you to make a striking design statement and add a touch of personality to your space. The process involves applying dyes to the surface of the polished concrete, which are then absorbed by the material, resulting in deep, long-lasting colors.

One of the main advantages of dyeing concrete is the wide range of color options available. Whether you prefer vibrant and intense hues or more subtle and earthy tones, there is a dye color to suit every taste and design concept. Dyes can also be used to create various effects, such as gradients or patterns, allowing you to unleash your creativity and achieve truly unique and eye-catching polished surfaces.

In addition to their visual appeal, concrete dyes offer practical benefits as well. They are known for their durability and resistance to fading, ensuring that your polished surfaces will maintain their vibrant colors for years to come. Moreover, dyes can be combined with other decorative techniques, such as stenciling or engraving, to create even more intricate and personalized designs.

Top Tips for Dyeing Concrete:

- Ensure the concrete surface is properly cleaned and prepared before applying the dye.

- Test the dye on a small, inconspicuous area of the concrete to ensure you achieve the desired color and effect.

- Consider using multiple dye colors to create depth and dimension in your polished surfaces.

- Seal the dyed concrete with an appropriate sealer to protect the color and enhance its longevity.

| Dyeing Concrete Advantages | Dyeing Concrete Considerations |

|---|---|

| Wide range of color options | Proper surface preparation is crucial |

| Ability to create unique patterns and designs | Test the dye on a small area before applying |

| Durable and fade-resistant colors | Consider combining dyes with other decorative techniques |

| Long-lasting vibrancy | Seal the dyed concrete for added protection |

“Dyeing concrete allows you to add a pop of color and create visually stunning polished surfaces. With a wide range of colors and the ability to create unique designs, dyeing concrete offers endless possibilities for customization.”

When considering dyeing concrete, it is important to work with professional concrete polishing contractors who have the expertise and specialized equipment for the job. They can guide you through the process, recommend the best dye options for your desired results, and ensure a flawless application. By partnering with professionals, you can achieve the vibrant, durable, and personalized polished surfaces you envision.

The Process of Polishing Concrete: A Foundation for Vibrant Designs

Before delving into the world of colored or dyed concrete, it’s essential to understand the process of polishing concrete, as it forms the foundation for achieving vibrant and stunning designs. Polished concrete is a versatile material that offers a customizable appearance while providing numerous benefits such as affordability, durability, low maintenance, and environmental friendliness. It is commonly used in areas with heavy traffic, such as warehouses, retail stores, hotels, and office buildings.

The process of polishing concrete involves grinding down the surface to a high-gloss finish, creating a smooth and reflective surface. This is achieved through a series of steps that include coarse grinding with diamond abrasives and progressively finer grinding to achieve the desired level of shine. Polishing concrete not only enhances its appearance but also increases its resistance to wear and tear, making it a practical and long-lasting flooring option.

To further enhance the design possibilities of polished concrete, colors, stains, and dyes can be applied. Pigments, acid stains, or water-based stains can be used to add color and create unique patterns or mimic the look of other materials like marble or wood. Concrete dyes, on the other hand, offer a wide range of vibrant and intense colors that can be used to create bold and vivid designs. Whether it’s a commercial space or a residential floor, polished concrete provides a solid foundation for incorporating creative and visually appealing elements.

The Benefits of Polished Concrete

- Affordability: Polished concrete is a cost-effective flooring option compared to other materials like hardwood or natural stone.

- Durability: Polished concrete is highly resistant to heavy traffic, scratches, and stains, ensuring long-lasting performance.

- Low maintenance: Polished concrete requires minimal maintenance, reducing the need for regular and costly upkeep.

- Environmental friendliness: Polished concrete utilizes existing concrete slabs, reducing the consumption of additional materials and contributing to sustainability.

When considering polished concrete for your next project, it’s important to hire professional concrete polishing contractors. These experts have the knowledge, experience, and specialized equipment required to achieve high-quality results. They can help you navigate the various design options and ensure that your polished concrete surface meets your aesthetic and functional requirements. So, whether you’re looking to add vibrant colors, create stunning patterns, or simply enjoy the benefits of polished concrete, we recommend consulting with professionals who can bring your vision to life.

| Pros | Cons |

|---|---|

| Cost-effective | Requires professional installation |

| Incredibly durable | Can be noisy when used in high-traffic areas |

| Low maintenance | May require regular resealing for added protection |

| Environmentally friendly | Surface can be slippery when wet |

Where Can Coloured or Dyed Concrete be Used? Versatility of Applications

The versatility of colored or dyed concrete extends to a wide range of applications, from residential floors to commercial spaces, offering endless possibilities for adding vibrancy and style. Colored or dyed concrete can transform any space, creating visually appealing environments that leave a lasting impression.

In residential settings, colored or dyed concrete can be used to enhance the aesthetics of floors, creating unique and personalized living spaces. Whether it’s a contemporary loft or a traditional home, colored or dyed concrete can add a touch of elegance and sophistication to any room. It can be applied in kitchens, living rooms, bedrooms, or even outdoor areas such as patios or pool decks, bringing color and character to these spaces.

In commercial spaces, colored or dyed concrete offers a durable and low-maintenance flooring solution that can withstand high foot traffic. From retail stores and hotels to office buildings and restaurants, colored or dyed concrete can create a polished and professional look. It can be used to highlight specific areas or create eye-catching patterns and designs in lobbies, hallways, or conference rooms, making a bold statement and enhancing the overall ambiance of the space.

Table: Versatile Applications of Colored or Dyed Concrete

| Residential Spaces | Commercial Spaces |

|---|---|

| Living rooms | Lobbies |

| Kitchens | Hallways |

| Bedrooms | Conference rooms |

| Outdoor patios | Retail stores |

| Pool decks | Hotels |

| Office buildings |

With colored or dyed concrete, the design possibilities are virtually limitless. Whether you prefer a subtle hint of color or a bold statement, colored or dyed concrete can be customized to suit your unique style and preferences. It can mimic the appearance of other materials, such as marble or wood, at a fraction of the cost, making it a versatile and cost-effective choice for any project.

To ensure the best results, it is recommended to work with professional concrete polishing contractors who have the expertise and specialized equipment for coloring or dyeing polished concrete surfaces. They can guide you through the process, help you choose the right colors or dyes, and ensure a flawless finish that will exceed your expectations.

The Benefits of Polished Concrete: Beyond Color and Design

In addition to its customizable appearance, polished concrete offers numerous benefits that make it a popular choice for residential and commercial spaces, including low maintenance requirements, high durability, and its eco-friendly advantages. Polished concrete is known for its ability to withstand heavy foot traffic and wear, making it ideal for areas with high usage, such as warehouses, retail stores, hotels, and office buildings. Its sleek and glossy finish not only enhances the aesthetic appeal of any space but also reflects light, creating a brighter and more open atmosphere.

One of the most significant advantages of polished concrete is its low maintenance requirements. Unlike other flooring options, polished concrete does not require any waxing, coating, or regular sealing. Routine cleaning with a mild detergent and water is typically sufficient to keep polished concrete looking its best. This means fewer expenses and less time spent on maintaining the floor, allowing you to focus on other important tasks.

Moreover, polished concrete is an environmentally friendly flooring choice. The polishing process utilizes existing concrete slabs, reducing the need for additional materials. This makes it an excellent option for those seeking sustainable solutions. Additionally, polished concrete does not release harmful volatile organic compounds (VOCs) into the environment, promoting better indoor air quality and a healthier living or working environment.

When it comes to durability, polished concrete is unmatched. Its dense surface resists stains, scratches, and impact, ensuring its longevity even in high-traffic areas. This durability translates to long-term cost savings, as polished concrete requires minimal repairs or replacements over time. With proper care, a polished concrete floor can last for decades, making it a wise investment for any space.

| Benefits of Polished Concrete: | Advantages |

|---|---|

| Low Maintenance | Requires minimal cleaning and upkeep |

| Eco-Friendly | Utilizes existing concrete slabs and does not release harmful VOCs |

| High Durability | Resistant to stains, scratches, and impact |

For those looking to enhance the aesthetics of their space while enjoying the benefits of polished concrete, the options are endless. Polished concrete can be colored, stained, or dyed to achieve a variety of effects and designs, allowing you to unleash your creativity and create a truly unique space. Whether you prefer a vibrant and bold color or a subtle and elegant stain, polished concrete can be customized to suit your preferences and complement your overall design scheme. To ensure the best results, it is recommended to work with professional concrete polishing contractors who have the expertise and specialized equipment to bring your vision to life.

Polished Concrete Safety: Slip Resistance and Maintenance Tips

While polished concrete is a durable and visually appealing flooring option, ensuring its slip resistance and proper maintenance are key to maintaining a safe and functional environment. Polished concrete surfaces can become slippery when wet or dirty, posing a safety risk. However, with the right precautions and maintenance practices, the slip resistance of polished concrete can be maintained effectively.

Slip Resistance

One of the main concerns with polished concrete is its potential for slipperiness, especially in areas prone to moisture or spills. To address this, it’s crucial to keep polished concrete surfaces clean and dry. Regular sweeping or vacuuming helps remove dust, dirt, and debris, minimizing the risk of slipping. For more thorough cleaning, use a neutral pH cleaner specifically designed for polished concrete floors.

Another effective way to enhance slip resistance is by applying an anti-slip treatment or coating. These products create a textured surface that improves traction, reducing the likelihood of accidents. It’s important to consult with a professional concrete polishing contractor to determine the most suitable anti-slip solution for your specific polished concrete flooring.

Maintenance Tips

Maintaining the beauty and functionality of polished concrete floors requires regular care and maintenance. Here are some essential tips:

- Wipe up spills immediately to prevent staining and slippery surfaces.

- Avoid using harsh cleaning agents or abrasive tools that can damage the polished surface.

- Place mats or rugs at entrances and high-traffic areas to minimize the accumulation of dirt and moisture.

- Use furniture pads or felt protectors to prevent scratching and scuffing.

- Periodically reapply a concrete sealer to maintain the protective layer and enhance the longevity of the polished finish.

By following these maintenance practices, you can keep your polished concrete floors in optimal condition, ensuring their safety and longevity.

| Benefits of Proper Maintenance | Consequences of Neglecting Maintenance |

|---|---|

|

|

By prioritizing slip resistance and adhering to proper maintenance practices, you can enjoy the beauty, functionality, and safety of your polished concrete floors for years to come.

Professional Concrete Polishing Contractors: Why Expertise Matters

When it comes to coloring or dyeing polished concrete surfaces, relying on the expertise of professional concrete polishing contractors can make all the difference in achieving the desired colors and finishes. Polished concrete is a versatile material that can be customized with various colors, stains, and dyes to create stunning and unique designs. However, this process requires specialized knowledge and equipment to ensure a successful outcome.

Professional contractors who specialize in concrete polishing have the experience and skills to handle the complexities of coloring and dyeing concrete surfaces. They understand the intricacies of the staining and dyeing processes, including the proper preparation of the concrete surface, the selection of suitable products, and the application techniques. With their expertise, they can help clients choose the right colors and finishes that complement their design vision and meet their specific needs.

Additionally, professional concrete polishing contractors have access to specialized equipment that is necessary for achieving high-quality results. This equipment allows for precise application of colorants and dyes, ensuring even distribution and vibrant colors. By utilizing professional-grade tools, contractors can enhance the aesthetic appeal of polished concrete surfaces and create a durable finish that will withstand heavy traffic and wear over time.

The Benefits of Hiring Professional Contractors

Working with professional concrete polishing contractors offers several benefits beyond expertise and specialized equipment. Firstly, they can save clients time and effort by efficiently completing the project, minimizing disruption to their daily routines. Contractors also have a deep understanding of industry standards and best practices, ensuring that the coloring or dyeing process adheres to safety regulations and quality standards.

Furthermore, professional contractors can provide valuable guidance and recommendations based on their extensive experience. They can help clients choose the most suitable coloring or dyeing options for their specific application and desired outcome. By leveraging their expertise, clients can avoid costly mistakes and achieve the desired colors and finishes that enhance the overall aesthetics of their space.

| Benefits of Hiring Professional Contractors | |

|---|---|

| Expertise in coloring and dyeing polished concrete surfaces | Ensures successful outcome |

| Access to specialized equipment | Enables precise application |

| Time and effort savings | Efficient project completion |

| Adherence to safety regulations and quality standards | Ensures a safe and high-quality finish |

| Guidance and recommendations based on experience | Helps clients make informed decisions |

In conclusion, the expertise of professional concrete polishing contractors is invaluable when it comes to coloring or dyeing polished concrete surfaces. By leveraging their knowledge, experience, and specialized equipment, contractors can ensure a successful outcome and create stunning colors and finishes that transform spaces. Clients can enjoy the numerous benefits of polished concrete, including affordability, durability, low maintenance, and environmental friendliness, while adding a touch of customization and vibrancy to their floors or surfaces.

Conclusion: Unleashing the Creative Potential of Polished Concrete

The world of polished concrete is full of creative possibilities, with colored, stained, and dyed concrete surfaces offering a versatile canvas to bring vibrant and personalized designs to life. Polished concrete is not just a practical flooring option; it is also a customizable one that allows you to create stunning visual effects and unique patterns.

By adding color to polished concrete, you can transform any space into an eye-catching masterpiece. Whether you prefer a subtle hint of color or a bold and vivid statement, the wide range of pigments and dyes available can help you achieve your desired aesthetic. Colored concrete can be used to create decorative patterns, borders, or logos, adding visual interest to both indoor and outdoor surfaces.

If you’re looking to achieve a natural, organic look, stained concrete is the way to go. Concrete stains penetrate the surface, creating beautiful variations and a unique appearance. You can choose from a variety of stains, including acid stains and water-based stains, to mimic the look of other materials like marble or wood. Stained concrete is a popular choice for adding warmth and character to residential and commercial spaces.

For those seeking vibrant and intense colors, dyed concrete is the perfect choice. Concrete dyes offer a wide range of colors and can be used to create stunning effects such as gradients or patterns. The dyes penetrate deep into the concrete, resulting in long-lasting and fade-resistant colors that truly stand out. Dyed concrete is ideal for creating bold and modern designs that make a statement.

When exploring the creative potential of polished concrete, it’s important to engage the expertise of professional concrete polishing contractors. They have the knowledge, experience, and specialized equipment to ensure quality results. With their help, you can unleash your creativity and transform any space into a visually appealing environment that reflects your personal style.

FAQ

Q: Can polished concrete be colored or dyed?

A: Yes, polished concrete can be colored or dyed to create a customizable appearance.

Q: What are the common applications of polished concrete?

A: Polished concrete is commonly used in areas with heavy traffic, such as warehouses, retail stores, hotels, and office buildings.

Q: What are the benefits of polished concrete?

A: Polished concrete offers numerous benefits, including affordability, durability, low maintenance, and environmental friendliness.

Q: Can polished concrete be used indoors and outdoors?

A: Yes, polished concrete can be used both indoors and outdoors and is suitable for various applications.

Q: How is concrete polished?

A: The process of polishing concrete involves grinding down the surface to a high-gloss finish.

Q: Can polished concrete surfaces be further enhanced with colors, stains, and dyes?

A: Yes, polished concrete surfaces can be enhanced with colors, stains, and dyes to achieve a desired aesthetic.

Q: Is polished concrete slippery?

A: Polished concrete is not slippery when kept clean and dry.

Q: Is polished concrete a sustainable flooring option?

A: Yes, polished concrete is a sustainable flooring option as it utilizes existing concrete slabs and reduces the need for additional materials.

Q: Should I hire professional concrete polishing contractors for coloring or dyeing polished concrete?

A: We recommend hiring professional concrete polishing contractors for this job, as it requires specialized equipment and expertise.