Mechanical Polished Concrete in Brisbane and Gold Coast

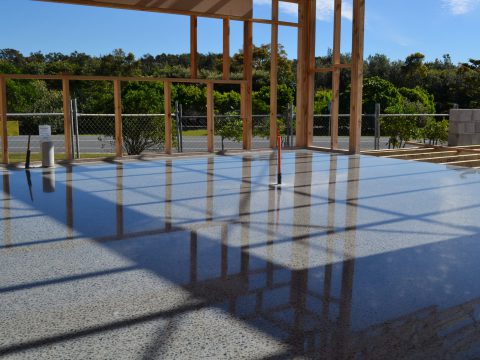

Mechanically Polished Concrete is an impressive yet sophisticated indoor flooring solution that Australian Flooring Group Pty Ltd recommend for indoor flooring surfaces only. There’s a reason why you see it in high-end hotels and ritzy real estate areas all across Australia. That’s because its a highly reflective, extremely durable, low maintenance concrete floor that lasts for ever. that will look amazing throughout your home, however is also a perfect solution for commercial buildings, retail flooring and offices in Brisbane, Gold Coast & Sunshine Coast. Unlike any other flooring finish, Mechanically Polishing Concrete creates highly polished surface, hard, dense and stain resistant surface without the use of any top coat sealants or coatings. By utilising the latest concrete polishing science, Australian Flooring Group Pty Ltd are able to provide a long-term flooring solution that does not need re coating and doesn’t disrupt the natural flow of traffic to the area with curing and dry time.

You may be wondering what mechanical polished concrete is, so let’s take a peek at what goes into it.

What is Mechanically Polished Concrete?

Concrete has come along way since its inception. What started as a rudimentary mix of water, sand, air, and gravel has really evolved over the years. Now there’s a dizzying array of different techniques to strengthen and beautify concrete.

Years ago, polishing concrete involved applying a layer of film coatings on top. These coatings created a stylish reflective look and were slip and abrasion resistant. The flaw in this technique was that the coating would only last for a short time. Once it scratched and started to wear, you would have to re-apply the coating. This was both time consuming and costly for the customer.

That’s where the brilliance of mechanical polished concrete comes into play. This process involves adding densifiers or hardening agents in between layers of grinding and polishing. The final step is to apply a penetrating sealer, which is NOT a topical coating. Instead, it’s absorbed deep into the concrete. In other words, it doesn’t lay on top of the concrete; it effectively becomes part of the concrete. As a result, there is no topical coating that will wear down over time.

Since no re-application is necessary, mechanically polished floors require little to no maintenance. They’re also resistant to staining, improve ambient light, and are easy to keep clean.

At Australian Flooring Group Pty Ltd, we use two main types of mechanical polished concrete. They are the Hiperfloor and Signature Floor systems. Let’s take a look at each to get a good understanding of the difference and benefits between the two.

Benefits of Mechanical Polished Concrete

Over time, various companies in the flooring industry throughout Brisbane, Gold Coast & Sunshine Coast have experimented with the original polished concrete method and have arrived at their own proprietary solutions. There are a couple of big brand names that come to mind when you think of mechanically polished concrete floors. Hiperfloor and Signature Floor.

Hiperfloor by Husqvarna is a trademarked concrete polishing system intended to enhance the natural look, and overall strength of concrete floors. This technique uses unique grinding machinery, diamond grinding segments and diamond polishing pads combined with a concrete densifier, all built and designed by Husqvarna. Australian Flooring Group Pty Ltd can offer up to a 10 year warranty on all residential Hiperfloor polished concrete in Brisbane, Gold Coast & Sunshine Coast and up to 5 years on commercial projects.

Australian Flooring Group Pty Ltd have worked tirelessly, constantly revolutionizing the concrete polishing method by weeding out flaws and enhancing current finishes. By designing and manufacturing our own concrete chemicals, diamond polishing pads and diamond grinding segments we were able to launch our own trademarked concrete polishing method – Signature Floor.

Signature Floor’s ‘ultra high gloss’ achieves a mirror-like shine that can be compared to no other polished concrete finish on the market.

Both Hiperfloor polished concrete and Signature Floor polished concrete offer 3 levels of aggregate exposure. Aggregate exposure is essentially grinding the concrete down to expose the natural stone embedded all throughout the slab of concrete on the floor. To do this Australian Flooring Group Pty Ltd uses our state of the art machinery, combined with specially designed metal grinding segments combined with diamond grits. These concrete diamond grinding segments are passed over the concrete approximately 3-4 times to achieve the desired exposure. With existing concrete, every concrete surface will have a unique look, each concrete will have differing amount of aggregate exposure and the finished product will depend solely on the existing concrete giving you an individual look exclusive to your desired requirements. We are able to carry out a very light concrete grind to remove 1-2 mm off the concrete surface, exposing minimal aggregate, or we can carry out a heavier concrete grind, removing 3-5 mm off the concrete surface to achieve the maximum exposure possible for that particular concrete. After the concrete grinding process is complete Australian Flooring Group Pty Ltd then uses specially designed polishing pads with finer diamond grits to pass over the concrete until it becomes a hardened polished surface. This process will continue approximately 4-6 times until the level of gloss finish desired is achieved. The concrete floor will then be seal with a natural look penetrating sealer to help prevent stains from accidental spills and general traffic.

Australian Flooring Group Pty Ltd can offer up to a 10 year warranty on all residential Signature Floor in Brisbane, Gold Coast & Sunshine Coast and up to 5 years on commercial jobs.

There are many reasons why mechanical polished concrete is ideal for indoor environments. They include:

- Slip, impact, stain, and abrasion-resistant

- No need to re-apply costly topical coatings

- Increases natural ambient light and is highly reflective

- Reduces costs for lighting, cleaning, and maintenance

- Has fantastic aesthetics and won’t fade or yellow over time

- Is very easy to keep clean

As you can see, mechanical and diamond polished concrete floors are genuinely fantastic. They look great, save you money, and are a breeze to maintain. Be sure to reach out to us at Australian Flooring Group Pty Ltd for a free estimate today!

So you’ve decided to install some mechanically polished concrete floors. Great! The next step is to decide on a few customizable options. You see, you can select your level of gloss finish and aggregate/stone exposure. The breakdown goes like this:

MECHANICALLY POLISHED CONCRETE FLOOR FINISHES

STEP #1 – Select your level of polished concrete aggregate exposure

- Australian Flooring Group Pty Ltd Cream Finish

Also know as Burnished Concrete. In this process, very little to none of the concrete surface is removed. Generally, no aggregate will be exposed with this chosen finish. Burnished concrete finish will retain the natural look and effect of the concrete surface. If there is undulation or imperfections in the existing concrete, this will still be present with a cream finish/burnished concrete. If you are installing new concrete, it is important to involve Australian Flooring Group Pty Ltd throughout the installation process in order to maintain the standard for installing the concrete prior to us polishing the surface. - Australian Flooring Group Pty Ltd Light Grind

Also known as a Salt and Pepper Finish. Removing approx. 1-2mm off the top of the concrete slab, this finish will faintly expose the natural aggregate giving it a light salt & pepper look. There is often no exposure in some areas, while others have a lot. This all depends on how the original concrete slab was poured. Australian Flooring Group Pty Ltd Light Grind is often used for its industrial design appearance and is also a popular choice for garages, offices and retail flooring. - Australian Flooring Group Pty Ltd Medium Grind

Taking approx. 2-3mm off the top of the concrete slab, this finish will expose an intermediate amount of aggregate showcasing small to medium size stones. Perfect for internal residential flooring whilst remaining cost efficient. - Australian Flooring Group Pty Ltd Heavy Grind

Taking approx. 3-5mm off the top of the concrete slab, this finish will give you the maximum stone exposure possible for your floor. Every concrete floor is different, even though we carry out a heavy grind, this does not guarantee that we will achieve a Full Exposure look. We will expose the most exposure possible with your particular concrete. This is our most popular choice as more large and medium size stones are exposed giving a ‘terrazzo like’ decorative effect, perfect for Internal Residential Flooring and showrooms.

By minimising the required amount of aggregate exposure, this generally means the costs per square meter are lower than exposing full aggregate.

STEP #2 – Select your level of gloss finish.

When deciding between Australian Flooring Group Pty Ltd’s gloss levels, it all comes down to personal preference and the look you are trying to achieve in the allocated space.

- Matte Finish Polished Concrete

An industrial/rustic finish, perfect for homes, retail flooring, food & beverage flooring and other commercial flooring. This finish is now being favoured by many designers wanting a raw material looks to go with furnishings. - Semi Gloss Finish Polished Concrete

A very popular finish widely used in homes and commercial projects. While still having great shine, the finish won’t show much dust or dirt on its surface making it perfect for high traffic areas. - High Gloss Finish Polished Concrete

This finish is the showstopper and head turner of all polished concrete floor finishes. With maximum shine, high gloss is chosen by people who want their floor to be the feature of the room, high end homes and showrooms. While requiring a little extra work then the other two options this incredible concrete finish is worth it.

STEP #3 – Gather your building plans, measurements and photos of your desired space and call Australian Flooring Group Pty Ltd on 1300 693 566, chat to one of our friendly team members and book in your free polished concrete quote in Brisbane, Gold Coast & Sunshine Coast.

We feature affordable prices and extensive warranties, so don’t wait to try us out.

Gallery

Top 10 reasons to choose Australian Flooring Group Pty Ltd

Floor solutions are delicate processes that take professionals to do correctly. That’s why you need to hire our team at Australian Flooring Group Pty Ltd. We’re by far the most experienced and reputable floor solution company in Queensland. You’ll be in great hands when you choose us, and there are many reasons why. Here are the top factors why we’re the best concrete polishing company out there today:

14 years in the business

Australian Flooring Group Pty Ltd is here for the long-term. We got started in 2009, and we’re not going anywhere anytime soon. In fact, we continue to grow and expand each year that we’ve been in business. Our longevity is due to our expertise and excellent service. We have superior product knowledge, and we’ve even crafted our own signature flooring solutions. Our team members have also mastered the art of problem-solving on the fly. As a result, we’re able to handle any issue that we encounter with total ease.

Small enough to care, large enough to deliver

We have a total of 8 team members at our company. To us, it’s the perfect sweet spot for us and our customers. We’re small enough to give a very personal touch while large enough to tackle giant projects. Our team can handle tasks that range in size from 20m2 to 20000m2. We provide commercial, residential, and industrial services, all with equal quality and dedication.

Stellar Google reviews

All it takes is one quick internet search to realize how great of a reputation we have. Currently, Australian Flooring Group Pty Ltd boasts almost 100 reviews with a 4.8 average score. All our reviews are candid and totally authentic. We believe our reviews speak for themselves, so don’t be shy about checking them out!

We add value with no complications

Whether our flooring solutions are for your business or home, we add serious value to our clients. Our polished concrete will save you money on electricity and energy, as well as add value to your home. For industrial environments, our no-slip coatings will keep your employees safe and protected. We’re in the business of adding value without complicating matters. The same can’t be said for our competitors!

QBCC Licensed

Most of the companies that you’ll find in Queensland are not certified. At Australian Flooring Group Pty Ltd, we boast our QBCC license, which allows us to carry out concrete coatings and polishing. It’s another mark of our professionalism and expertise.

Ongoing support for our clients

Our services don’t end when we finish with your flooring solution. We’ll educate you on adequately maintaining your floor, and we can perform minor repairs and fixes for you. We value you as our client, and it’s our goal to secure your long-term business. That’s why we won’t hesitate to go above and beyond for you.

Professional team support

We boast incredible attention to detail in our services. We also keep an open line of communication with our team and clients. You’ll always be able to get a hold of us if you have any questions or concerns.

Quality control

We have rigorous measures in place to ensure our quality stays the same every time. Our project managers mean business, and they check up on all our job sites. They’ll also keep in touch with you to ensure your satisfaction during the entire process.

Pre-installation meeting

We’ll consult with you in great detail on what you want out of your flooring solutions. That way, you’ll have complete control over how your flooring installation goes.

Specialists will provide you with extra knowledge

We’ve been in business for 14 years, and we’ve accrued tons of knowledge during that time. Educating our clients is also a big part of what we do, so don’t be shy about asking questions!

FAQ

One of the most fantastic features of Australian Flooring Group Pty Ltd mechanically polished concrete floors is that it has NO curing time and NO drying time, meaning once the job is complete, daily activities can resume immediately. Australian Flooring Group Pty Ltd have a highly trained and dedicated team, who get the job done in a timely matter and at the highest quality. Depending on the level of polished concrete aggregate exposure & level of gloss finish you have chosen for your floor and the job size, the time from start to finish may differ however a more precise time frame can be obtained when a Australian Flooring Group Pty Ltd representative is quoting your job.

Australian Flooring Group Pty Ltd provides advise on maintaining your new mechanically polished concrete floors upon completion of your job and offers ongoing support long after, happy to answer any questions over the phone or via email. One of the great benefits of having Australian Flooring Group Pty Ltd install your mechanically polished concrete floor is it needs next to no maintenance. A daily dry mop is recommended to pick up any dirt that has been brought onto the surface during the day’s activities. We recommend a damp mop be carried out once or twice a week depending on the amount of traffic in the area. A mild detergent should be used here mixed with warm water. Stay away from the use of bleach, vinegar, citrus, ammonia or any other cleaners that are inherently alkaline or acidic. As a final step Australian Flooring Group Pty Ltd recommends a damp mop with fresh clean water to remove any dirty residue from the floor. This will ensure that the gloss shine will stay bright.

Hiperfloor and Signature Floor can be installed after the frame and roof has been fitted, prior to gyprock being installed which is generally a lot more cost effective than waiting until after construction has been completed. As this polished concrete finish is more durable and no surface sealers or coatings are applied during the process, they will not get easily scratched or damaged during construction. As concrete needs to breathe it is important the finished floor is not covered up. This will create a moisture lock, which in turn causes the concrete to sweat and will deteriorate the finish (making your glossy floor turn dull, and any grouting to holes/cracks will fall out).

Yes, Australian Flooring Group Pty Ltd can remove any/all existing flooring including any underlying adhesives or floor toppings for an additional cost. Australian Flooring Group Pty Ltd will also patch and repair any holes or damage in the existing concrete during the polishing process to provide you with a seamless floor.

Yes, Australian Flooring Group Pty Ltd can carry out an ‘Industrial Finish’ where no aggregate is exposed at all. There are several important requirements to ensure we can achieve this finish so it’s best to contact us for advice prior to having the concrete installed.

Trusted Past Clients

What our clients say

Enquire now

we would love to hear from you

Enquiry Form

Call us today so we can design a cost

effective solution for your next project.

Our Services and Locations

Polished Concrete in Gold Coast